SBC valve guides are critical components in small block Chevrolet engines, ensuring proper valve alignment and preventing oil leakage. Made from durable materials like manganese bronze, they enhance engine performance and longevity by maintaining cylinder head integrity and reducing wear on moving parts.

1.1 Brief Overview

SBC valve guides are essential components in small block Chevrolet engines, designed to ensure proper valve alignment and prevent oil leakage. They are typically made from durable materials like manganese bronze or hardened steel, offering resistance to wear and tear. These guides are crucial for maintaining engine performance, as they stabilize the valves and facilitate smooth operation. Compatible with various SBC engines, including Chevrolet, Ford, and Chrysler models, they are a fundamental part of both new engine builds and replacement projects, ensuring reliability and longevity.

Function and Importance in SBC Engines

SBC valve guides ensure proper valve alignment, prevent oil leakage, and maintain engine performance. They are vital for longevity, stabilizing valve movement, and optimizing combustion efficiency in SBC engines.

2.1 Role in Engine Performance

SBC valve guides play a crucial role in maintaining engine performance by ensuring proper valve alignment and reducing wear. They prevent oil leakage, which can lead to decreased efficiency and increased emissions. By stabilizing valve movement, they contribute to consistent combustion and power delivery. Durable materials, such as manganese bronze, enhance longevity and resistance to heat and friction. Properly functioning valve guides minimize engine noise, improve fuel efficiency, and maintain optimal engine operation. Their role is essential for sustaining peak performance and reliability in SBC engines over time.

Symptoms of Worn Valve Guides

Common symptoms include increased oil consumption, excessive smoke, and engine noise. Worn guides can cause poor engine performance, reduced power, and potentially lead to costly repairs.

3.1 Common Indicators of Wear

Key indicators of worn SBC valve guides include excessive oil consumption, blue smoke from the exhaust, and a tapping or clattering noise from the engine. Additionally, decreased engine performance, rough idling, and increased emissions are common signs. Over time, worn guides can lead to significant damage to the cylinder head and valves, necessitating costly repairs. Regular inspection and maintenance are crucial to prevent such issues and ensure optimal engine operation.

Types of SBC Valve Guides

SBC valve guides are available in various materials, including manganese bronze and hardened steel, offering durability and resistance to wear. They come in standard and oversized versions.

4.1 Materials and Designs

SBC valve guides are crafted from durable materials like manganese bronze and hardened steel, known for their resistance to wear and heat. Designs vary, with standard, oversized, and self-aligning options available. Manganese bronze guides offer excellent durability and lubricity, while hardened steel provides enhanced strength for high-performance applications. Some designs feature precision CNC machining for exact fitment. These materials and designs ensure proper valve alignment, reduce oil consumption, and maintain engine performance over time. The choice of material and design depends on the engine’s specific needs and operating conditions.

Installation Guide and Process

Installing SBC valve guides involves drilling out old guides, fitting new ones, and ensuring proper alignment. A complete valve job often follows to ensure optimal engine performance.

5.1 Step-by-Step Installation Instructions

- Remove the old valve guides by drilling them out carefully to avoid damaging the cylinder head.

- Inspect and clean the guide bores to ensure proper fitment of the new guides.

- Install the new valve guides using a specialized driver or installation tool to seat them correctly.

- Ream the guides to the correct diameter for the valve stems.

- Perform a valve job to cut the seats and ensure proper sealing with the new guides.

- Reassemble the engine and test for leaks or improper valve operation.

Tools and Equipment Needed

Essential tools include a valve guide installer, drill bits, guide reamer, valve seat cutter, and a driver to ensure precise installation and proper fitment of new guides.

6.1 Essential Tools for Replacement

Replacing SBC valve guides requires specialized tools, including a valve guide installer and reamer to ensure precise fitment. A drill press and bits are necessary for removing old guides, while a valve seat cutter prepares the area for new guides. Additional tools like a driver and alignment jig help maintain accuracy. These tools ensure the replacement process is efficient and prevents damage to the cylinder head, making the job safer and more effective. Proper equipment is crucial for achieving professional results and avoiding costly repairs down the line.

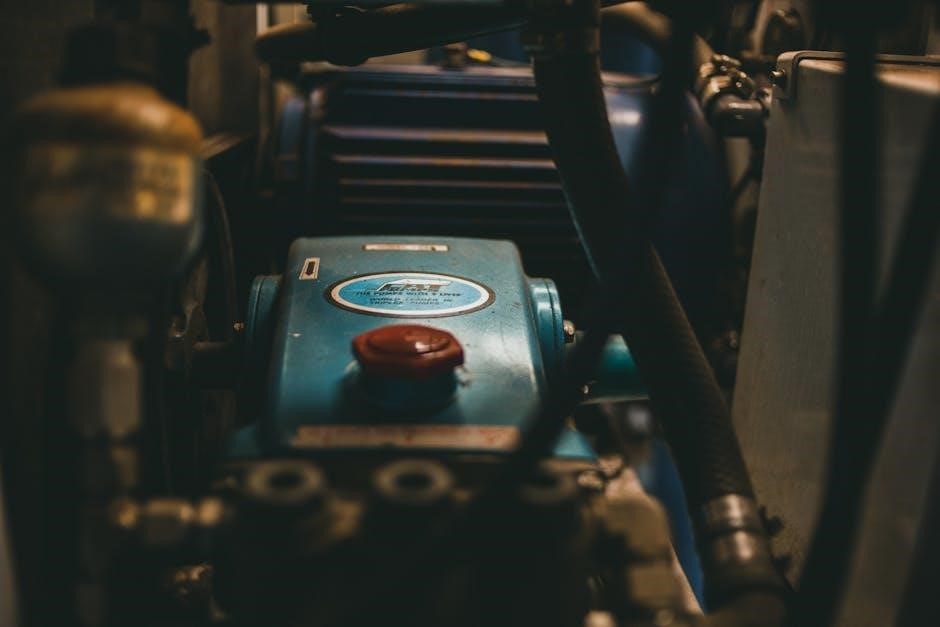

Case Study: Successful Replacement

A successful SBC valve guide replacement was documented by John at Costa Mesa R&D Automotive Machine, showcasing expertise in the process using specialized tools and techniques.

7;1 Real-World Example of Replacement

A real-world example of SBC valve guide replacement involved a small block Chevrolet engine with worn guides causing oil leakage and reduced performance. John at Costa Mesa R&D Automotive Machine demonstrated the process, utilizing specialized tools to drill out the old guides and install new manganese bronze ones. The procedure included reaming, fitting, and sealing the guides to ensure proper alignment and oil containment. Post-installation, the valves and seats were cut to specification, and a leak test confirmed the repair’s success, restoring engine efficiency and longevity.

Maintenance Tips for Longevity

Regular inspections, proper lubrication, and avoiding overheating are key to extending valve guide life. Use high-quality materials and ensure cleanliness during installations to prevent premature wear.

8.1 Best Practices for Maintenance

Regular inspections and proper lubrication are essential for extending valve guide life. Use high-quality materials and ensure precise fitment during installation to minimize wear. Avoid overheating, as it can degrade guide materials. Cleanliness is crucial—remove contaminants before installing new guides. Lubricate moving parts to reduce friction and prevent premature wear. Avoid using abrasive materials that could damage the guides or surrounding components. Follow manufacturer guidelines for torque specifications and alignment. Schedule periodic checks to identify and address potential issues early, ensuring optimal engine performance and longevity.

Common Mistakes to Avoid

Improper drilling, misalignment, and using incorrect materials can damage cylinder heads. Avoid over-tightening or using abrasive tools, as this may lead to premature wear or guide failure.

9.1 Errors to Avoid During Installation

- Improper drilling of original guides can damage cylinder head threads.

- Misalignment during installation leads to uneven wear and reduced performance.

- Using incorrect materials may result in premature wear or failure.

- Over-tightening can cause cracking or stress on the cylinder head.

- Not using proper tools risks damaging the guides or surrounding components.

- Insufficient cleaning of the head before installation can lead to poor fitment.

DIY vs Professional Installation

DIY installation is cost-effective but requires precise tools and expertise. Professional installation ensures proper fitment and longevity, though at a higher cost. Choose based on your skill level.

10.1 Pros and Cons of Each Approach

DIY installation offers cost savings and hands-on experience but demands specialized tools and technical expertise. Professional installation ensures precise fitment and warranty but is more expensive. Choose DIY if confident in your skills; otherwise, opt for professional services to avoid costly errors.

Parts and Manufacturer Guide

Top manufacturers like GSC Power-Division, Elgin, and GM offer high-quality SBC valve guides. These parts are crafted from durable materials such as manganese bronze for optimal performance. Ensure compatibility by selecting guides designed specifically for your engine model. Purchase from reputable suppliers or online platforms like eBay to guarantee authenticity and reliability. Always verify part numbers and specifications before ordering to ensure a perfect fit for your SBC engine.

11.1 Compatible Parts and Manufacturers

Reputable manufacturers like GSC Power-Division, Elgin, and GM offer compatible SBC valve guides. These guides are precision-engineered from materials such as manganese bronze for durability. Popular part numbers include TFS-51400252 and TFS-51700252, designed for Ford and Chevrolet applications. Additionally, New Box of 50 Cast Iron Valve Guides (11/32 x .502) is a reliable option for SBC Chevy and Ford engines. Always verify compatibility with your engine model and specifications before purchasing. Ensure to buy from trusted suppliers or platforms like eBay to guarantee authenticity and quality.

Troubleshooting Post-Installation

Common issues include oil leakage, misaligned valves, or improper seating. Inspect guide-to-stem clearance and reseat valves if necessary. Adjust rocker arms for alignment and ensure guides are securely installed.

- Symptoms: Excessive oil consumption, reduced performance, or engine noise.

- Solutions: Verify guide installation, check for wear, and re-machine if needed.

12.1 Common Issues and Solutions

Post-installation issues with SBC valve guides often include oil leakage, misaligned valves, or improper seating. Inspect guide-to-stem clearance and reseat valves if necessary. Adjust rocker arms for proper alignment and ensure guides are securely installed. Excessive oil consumption or engine noise may indicate improper installation or wear. Verify guide installation, check for wear, and re-machine if needed. Always use specialized tools for precise measurements and adjustments to avoid further damage. Addressing these issues promptly ensures optimal engine performance and longevity.

- Symptoms: Excessive oil consumption, reduced performance, or engine noise.

- Solutions: Verify guide installation, check for wear, and re-machine if needed;

Future Trends and Innovations

Advancements in materials and manufacturing are driving innovations in SBC valve guides, with developments in proprietary alloys and CNC precision improving durability and reducing oil consumption.

13.1 Innovations in Valve Guide Technology

Innovations in SBC valve guide technology include advanced materials like proprietary manganese bronze alloys and precision CNC machining, enhancing durability and oil consumption reduction. Modern designs focus on improved heat resistance and wear resistance, ensuring prolonged engine performance. Additionally, manufacturers are exploring coatings and surface treatments to minimize friction and extend lifespan. These advancements aim to meet the demands of high-performance engines while maintaining compatibility with various SBC applications, ensuring reliability and efficiency for both classic and modern setups.